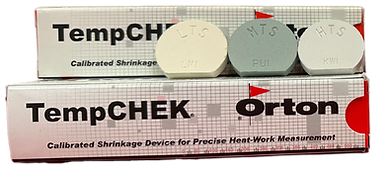

TempCHEK

The practical use of TempCHEK is for verification of the thermal uniformity and reproducibility of heat work delivered by a specific heating profile. TempCHEKs provide an easy method to digitize and record the firing process by using a digital micrometer to measure the final TempCHEK dimension, entering the dimension into the TempCHEK Trakker software that translates the final dimension into a temperature equivalent.

TempCHEKs are used widely in the Structural Clay and Investment Casting Industries but can also be used in Advanced Ceramics, Refractories, Sintering Dental Implants, Whitewares and Grinding Wheel Industries. TempCHEKs are made from carefully controlled ceramic materials that shrink over a fairly wide temperature range. They are measured once they have been exposed to the firing process and their dimension is used to determine the peak temperature they were exposed to.

The value of the TempCHEK is to provide verification that the kiln is delivering the expected amount of heat work each time a specific heating profile is applied and verify that the heat work is being delivered uniformly within the kiln ware load when multiple TempCHEKs are placed within the load setting. Software is available to automatically track your process temperatures for up to 9 locations by simply inputting the TempCHEK dimensions from each location after each firing. Temperatures are developed in air at a ramp rate of 1 degrees C per minute up to the setpoint with a 60 minute hold time. A correction graph is provided for hold times other than 60 minutes.

Ceramic Materials go through important changes as they are heated in a kiln, changes that are necessary to develop specific properties. To produce a quality product, control over the heating cycle is known to be a critical variable in developing key product attributes. Control of temperature alone is not an effective method for producing a quality product. Ceramic materials are affected by both the temperature and the length of time they are exposed to temperature. Properly monitoring both the time and temperature are essential for maintaining control. TempCHEK measure the amount of energy input into the firing process, commonly referred to as heat-work, the combined effect of time and temperature. TempCHEK are made from ceramic materials similar to those associated with producing ceramic products. Therefore, the TempCHEK react to heat-work in the same manner as the ware. A key reaction that ceramic materials undergo when heated is densification as observed by shrinkage. Orton has developed the TempCHEK to undergo a high degree of shrinkage so it can be used to measure the heat-work within your process by precise measurement of its shrinkage. The shrinkage measurement, when converted to a heat-work temperature, can represent the success or failure to reach a desired fired property.

Orton produces 3 versions of TempCHEK covering the following temperature ranges;

Low Temp

850°C - 1100°C (1560°F - 2010°F)

Medium Temp

950°C - 1100°C (1740°F - 2010°F)

High Temp

1075°C - 1420°C (1970°F - 2580°F)

Why use TempCHEK and when are they used?

- For Process improvement

- For monitoring process control

- For Preventative maintenance

The actual temperature inside a kiln when measured by a thermocouple does not give a true representation of the amount of heat absorbed by the product within the kiln. A thermocouple can only report the temperature at a fixed location, usually in the roof or along the sidewall of a kiln. TempCHEK can be placed anywhere within the kiln to determine the amount of heat-work at that location. The TempCHEK report the amount of energy absorbed over time within the ware setting by radiation, convection, and conduction. The heat-work measurements can be used to monitor and improve the uniformity and repeatability of the process.

Thermocouples and electronic equipment used to control kilns are effective tools, but are subject to errors. Thermocouples can degrade over their useful life and can break without warning. Electronic controllers need to be calibrated and can drift off calibrated settings over time, all the while reflecting a false temperature reading. Since TempCHEK are not subject to degradation, they can be relied on to report actual changes in the process. Through daily use, they can be used to spot trends and react to them before the product is adversely affected.

Can they be used for Statistical process Control?

Yes, using the Orton TempTracker software, up to nine locations can be monitored within a kiln to ascertain the uniformity of the kiln and the repeatability of the process. Adjustments to gas burners or power outputs, dampers, ware setting patterns, and air flows can be noted on the control chart generated by the software and the reflected changes can be monitored. Further fine tuning can be conducted until a steady state is achieved. Orton provides the TempTracker software free to all of its customers.

How are they measured?

Gather the TempCHEK after completion of the firing cycle, measure the fired diameter using the Orton Desktop gauge. Each TempCHEK can be labeled beforehand using a high temp marker or inscribing some identification into them with a scribe or the tip of a nail. It is best practice to place the TempCHEK in as close to the same location every time. Enter the measurement into the TempTracker software and monitor the results.

How is the shrinkage transferred to temperature?

Orton conducts several firings in a tightly controlled kiln to generate data for the shrinkage conversion tables they provide with each batch of TempCHEK. Orton engineers use a set heating profile when conducting calibration firings. The profile uses a final heating rate of 60°C/hr followed by a one hour hold at peak temperature. Additional data is available for adjusting the heat-work temperature for hold times greater or less than the standard one hour hold time. The TempCHEK temperature is a representation of the amount of heat-work absorbed. The temperature associated to the shrinkage value does not represent actual temperature. For customers wanting to maintain even tighter control, Orton can work with you to develop firing data specific to your thermal profile, produce and set aside a specific batch of TempCHEK to last for an extended period of time, or set up blanket releases of product to spread out cost.

Tables are available with each batch so the fired dimension can be turned into an equivalent temperature

Product features and benefits

-

Provides independent process temperature verification

-

Able to easily monitor temperatures in the load

-

High sensitivity to process changes

-

Temperatures reported do not drift over time

-

Cost effective

-

Easy to use

-

Shelf stable

-

Free software

-

Product identification on each part

-

Highly accurate gauge available for use with software

-

Technical support from Orton

To speak with an expert

or call +1-614-818-1343

_edited.png)